Real World Innovations & Solutions

Located in the heart of Toronto, the mining finance capital of the world and home to more than 1,600 mining company headquarters, the Lassonde Institute of Mining is uniquely situated to strengthen our strategic partnerships with industry while maximizing impact and providing training opportunities for our students.

Our industry partners work closely with our researchers and students, and leverage their investments in research (by as much as a three times) through a variety of government matching programs, including the Natural Sciences and Engineering Research Council and the Ontario Centres of Excellence. This enables industry to achieve the greatest possible impact and return on investment on collaborative projects.

To learn more how to partner with us please contact , Director | Strategy & Development (civ.communications@utoronto.ca)

WHY PARTNER WITH LASSONDE INSTITUTE

Maximize Your ROI

Collaborating with our industry partners and members — together we create innovations for the mining industry

World-Class Expertise Across All Disciplines At U of T

Actively promoting a cross-disciplinary culture that emboldens unconventional mining research collaborations and partnerships

Recruit Top Talent

Our research exploration focuses on sustainable solutions strengthening the future of our communities and planet

Save Time and Money: Use Our Research Infrastructure

Collaborating with our industry partners and members — together we create innovations for the mining industry

Clear and Balanced Intellectual Property (IP) Terms

Actively promoting a cross-disciplinary culture that emboldens unconventional mining research collaborations and partnerships

Canada's Leading Mining Research, Innovation & Training

Our research exploration focuses on sustainable solutions strengthening the future of our communities and planet

INDUSTRY PARTNERSHIPS & INNOVATIONS

Improved Environmental Performance & Closure Strategies

Industry Challenge

Every year mines use 7 to 9 billion cubic metres of water to extract desired elements from raw ore, resulting in large volumes of tailings. Tailings ponds are often black boxes containing largely undescribed bacteria and other microorganisms that thrive on mineral wastes and drive chemical reactions that can lead to acidification, toxicity and oxygen consumption.

Innovation & Real-World Impacts

Unravelling the roles played by microbes in wastewaters geochemical processes allows companies to effectively manage and monitor while lowering costs and environmental risks.

Through the application of genomics with comprehensive geochemical analyses and modelling of micro-organisms to wastewaters, robust decision-making frameworks and accurate monitoring technologies have been designed.

Strategic Research Partners

Syncrude Canada, Glencore, Vale, Hudbay, Rambler as well as the Ontario Mining Association, NRCan and the Mining Association of Canada.

Cleaning Hard-to-Access Underground Reservoirs of Pollutants Naturally and Safely

Industry Challenge

Benzene, toluene, ethylbenzene and xylene, collectively known as BTEX, are major contaminants resulting from extraction, transportation and refining processes which frequently pollute groundwater. Their removal from soil and wastewater can be expensive and time consuming for industry.

Innovation & Real-World Impacts

Developing and delivering bio-remediation strategies and monitoring tools tackle and destroy BTEX chemicals. Lab-grown microorganisms can be added back to the soil to speed up the natural process of degradation. From transforming mining waste into new products and creating bio-based plastics from fuels, this research takes harmful materials and re-imagines their application.

Strategic Research Partners

Ontario Genomics, the province of Alberta, SiREM, Federated Cooperatives Limited, Imperial Oil Limited, and three Universities: Toronto, Alberta and Waterloo.

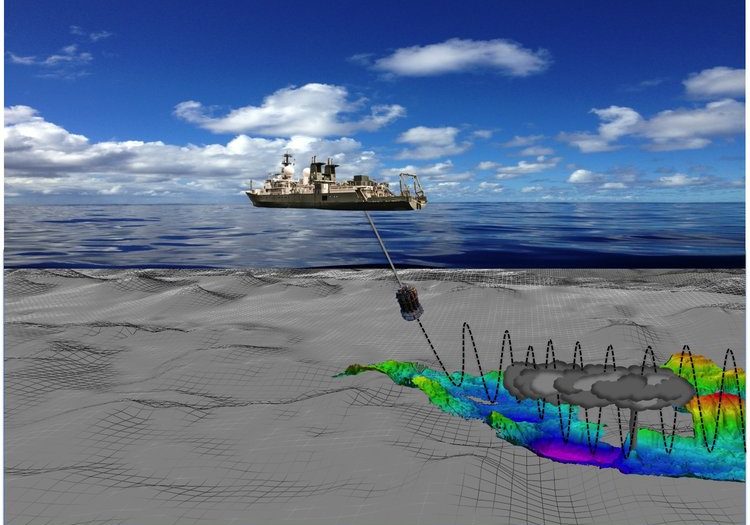

Unmanned & Remotely Operated Underwater Vehicles

Industry Challenge

Increasing demand for base and precious metal resources, coupled with declining discovery rates, is now encouraging the search for alternatives, including mining on the seafloor.

Innovations & Real World Impacts

The deep sea is a technically-challenging place to explore. We use a number of tools during sea-going research expeditions for a number of purposes:

- To map the seafloor topography and structures, we use: ship-based multibeam bathymetry, acoustic backscatter, side-scan sonar, and high-resolution bathymetry from Autonomous Underwater Vehicles (AUVs).

- To locate hydrothermal vent sites through water-column surveys, we use: Conductivity-Temperature-Depth (CTD) devices and Mini-Autonomous-Plume-Recorder (MAPR) devices.

- To observe the seafloor and take samples, we use: Remotely Operated Vehicles (ROVs), TV-grabs, dredges, sediment corers, wax corers, and fluid samplers.

- To measure geophysical characteristics of the seafloor, we use a wide range of geophysical equipment, including: magnetometers, seismic reflection/refraction systems, and Ocean Bottom Seismometers (OBSs).

Rock Damage & Dynamics Research For Mine Safety

Industry Challenge

Rock failure in the form of rock bursts can pose dangerous risks to underground operators. This failure is caused by accumulated rock damage due to stress or by damage plus stress wave disturbances of nearby blasts or earthquakes.

Innovations & Real World Impacts

New methods for exploring the failure mechanism of stressed rocks and quantifying field rock damage will lead to an improved understanding of risk and optimal safety strategies for our most precious resource: People.

These methods can be applied to underground blasting, mitigating the occurrence of rock bursts, minimizing the consequences of earthquakes, and predicting the stability of rock masses by monitoring field rock damage accumulation.

Optimizing Drill and Blast Techniques to Enhance Production

Industry Challenge

Predicting rock fragmentation in a drill and blast scenario can improve production and safety, decrease fly rock, improve slope stability and maximize the impact of the explosive energy usage.

Innovation & Real-World Impacts

Designing cost-effective predictive models for rock fragmentation in blasting as well as drilling to reduce overall mining costs, improve mining excavation operational safety and increase the life of mining operations. Determining effective methods of extraction helps industry partners remain competitive in the world market.

© 2026 Faculty of Applied Science & Engineering